Geometry and materials have well-known effects on the acoustic and mechanical properties of speakers, so they will also affect the recovery performance of speakers. No manufacturer can avoid diffraction, interference, resonance and fractionation. All films are related to their shape and material.

For the same material, each geometry has its own radiation characteristics, including diffraction and interference phenomena, which are responsible for the directionality and mutation of off-axis pressure at high frequency.

Under the same shape, each material has its linear and nonlinear vibration behavior, including resonance and splitting phenomena, which will lead to amplitude and phase accidents and affect directivity and harmonic distortion.

Introduction

Regardless of the diameter, geometry or properties of the film (treated paper, magnesium, ceramics, polypropylene, aluminum or other composite materials), and regardless of the motor (magnet, movable coil), all speakers have the best film operating limits. This limitation is characterized by the maximum frequency, that is, the axial displacement of the membrane is no longer completely uniform.

In electroacoustic terms, this phenomenon is also called "fragmentation of moving crew", which means that in the case of vibration and too fast vibration, the membrane will deform and become a flat bottomed ship, Ripples are generated to reproduce fully audible resonances, which are transmitted to the audience through more or less colors of sound information.

Here's how PM filtering solves this problem

The first sign of fragmentation of most accent and midrange speakers occurs at too low a frequency that the tweeter cannot answer in time because the tweeter is not suitable at all.

In fact, this frequency depends largely on the stiffness of the film and therefore on the material constituting the film. Only a 17 cm "standard" speaker is equipped with a so-called "soft" film made of polypropylene, paper or other variants, with a frequency of about 800 Hz.

Unfortunately, even the best performance high fidelity tweeters cannot be designed to reduce the frequency to such a low level due to their small emission area. Therefore, there is no choice but to allow the bass / midrange speakers to copy the frequency range in a distorted manner. This partly explains why all acoustic enclosures have different sounds.

Membrane selection

Therefore, in order to reproduce music in an absolutely transparent manner, it must be ensured that there is no film deformation in the entire audible bandwidth (20hz-20000 Hz). Pure motion filtering technology meets this requirement and ensures that the loudspeaker has good mechanical performance without splitting the mobile crew.

That's why all our speakers are equipped with very strong diaphragm speakers made of aluminum or aluminum / magnesium alloy. The following is a typical behavior comparison of soft (right slider) and hard (left slider) films for speakers with a diameter of 18 cm.

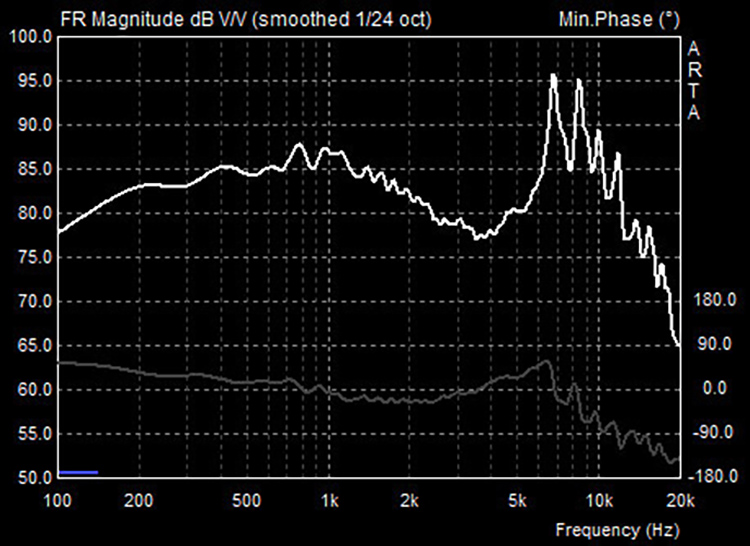

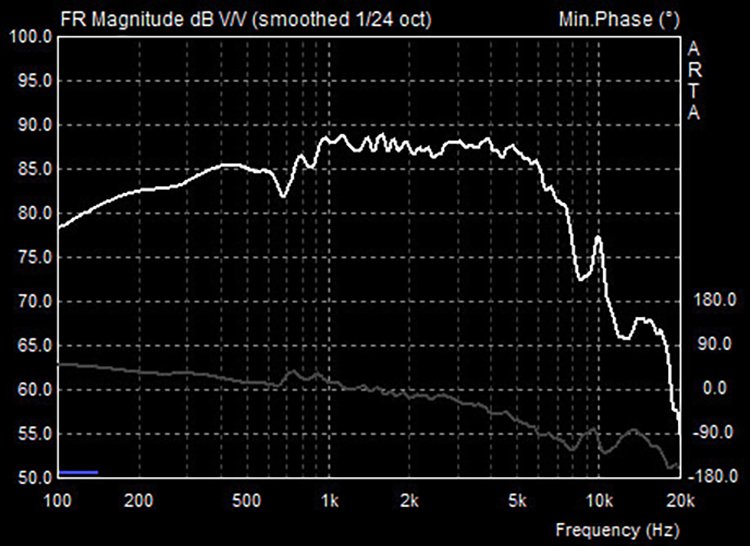

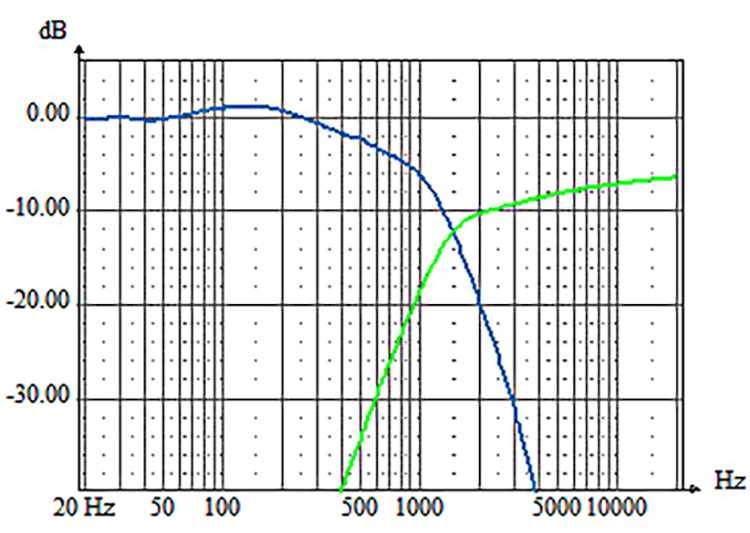

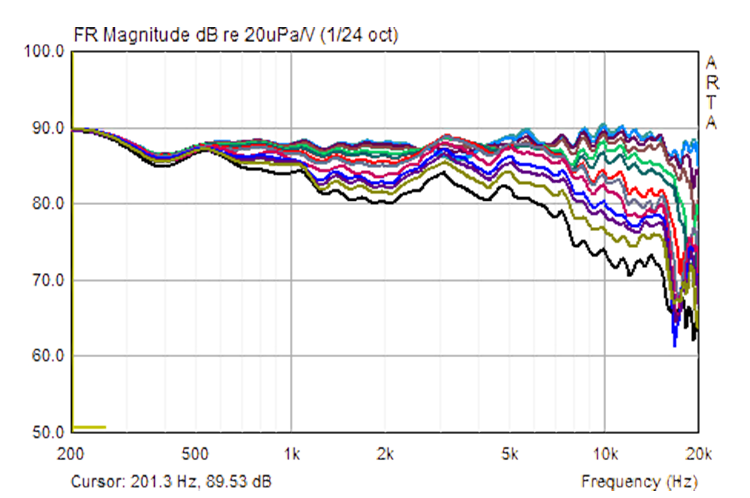

Response

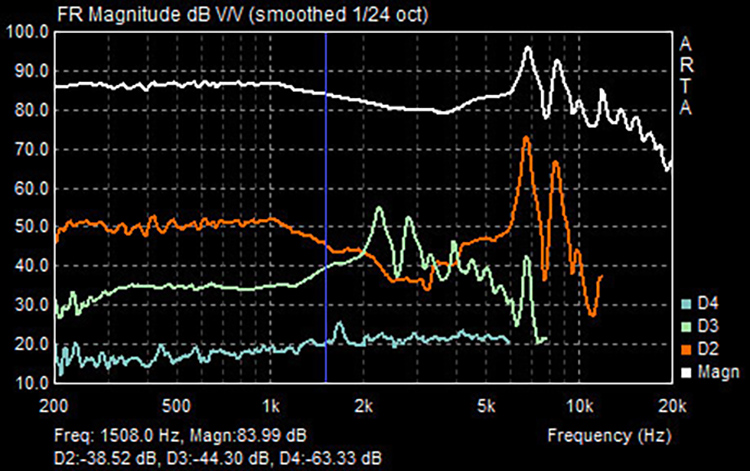

Soft membrane 700Hz frequency response accident, first shunting sign.

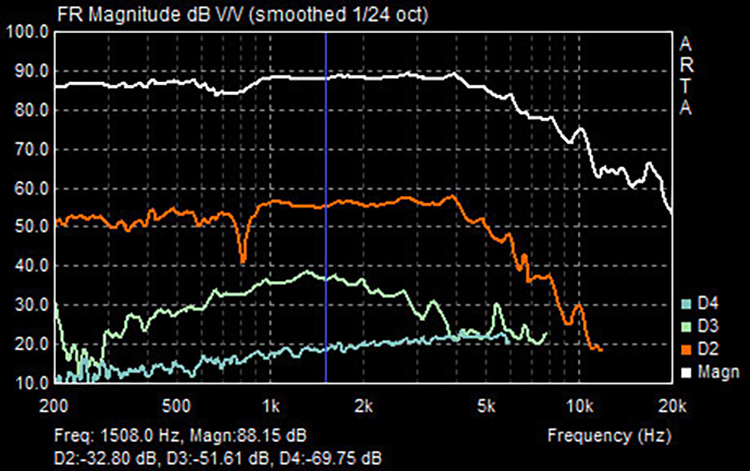

Rigid membrane, Resonance is very obvious and occurs only at 5KHz.

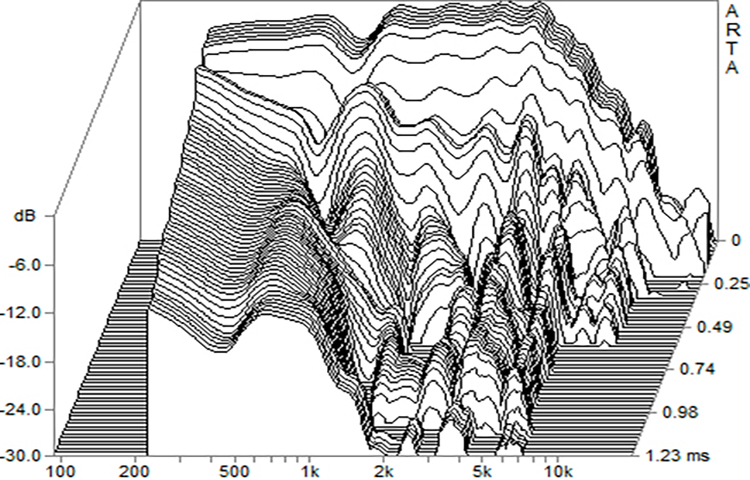

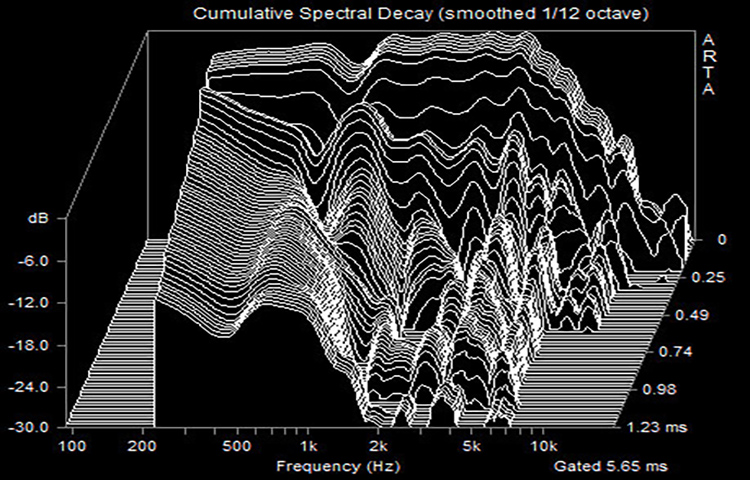

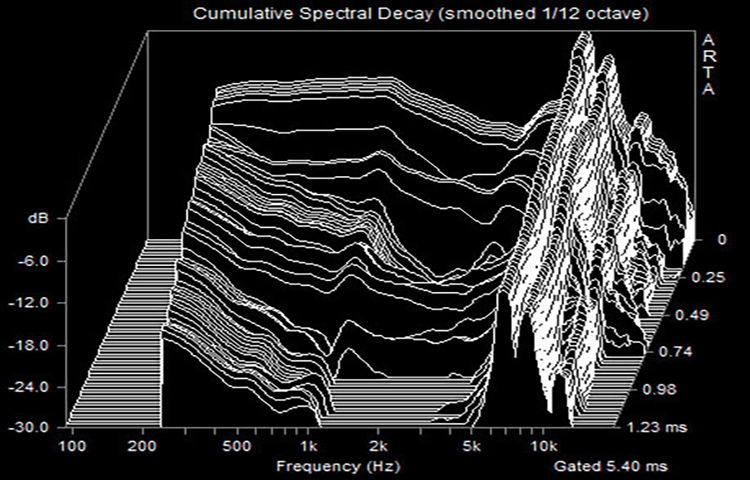

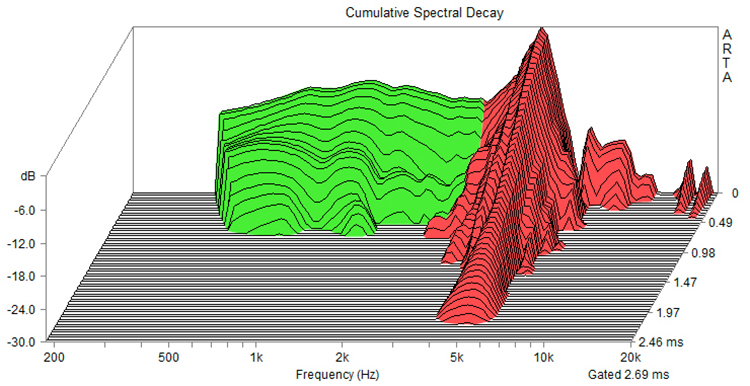

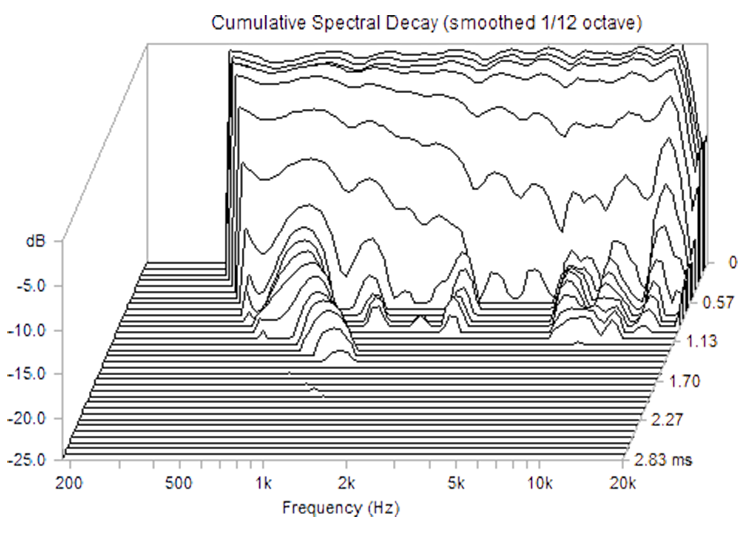

CSD

Soft membrane, Many resonance and sound signal sources occur in the low frequency band.

Rigid membrane, The resonances are concentrated at frequencies above 5KHz.

Distortion

Soft membrane, Uniform distortion over the entire useful bandwidth.

Rigid membrane, Resonant amplification of 2nd and 3rd harmonics requires specific filtering (PM)

Filter

In order to apply this technology, we use sensors equipped with very hard metal films. Their resonance seems to be concentrated at higher frequencies, far beyond the effective frequency range we transmit through each speaker.

Through filtering, all speakers work "piston" in all useful working ranges, which enables auditory audio speakers to reproduce music without adding any color.

Optimization

Like traditional filters, this passive filtering technology ensures the segmentation and redistribution of music signals on each speaker. However, pure motion filtering goes further in optimizing the transfer function, so as to accurately respond to the inherent acoustic characteristics of speakers and speakers.

The pure motion filter is equipped with very high-quality passive components and integrates adaptation and compensation, so that the shell has unparalleled transparency and neutrality.

The signal separation is between 6-24db / OCT and has a low cross frequency (or cut-off frequency) to ensure that the membrane is not affected by mechanical resonance.

Therefore, we carefully apply this overlap to a frequency at least three times lower than the first resonant frequency of the film. This preventive measure makes the distortion of the speaker very low and can accurately reproduce the sound information.

Pure motion filtering technology, with its atypical treble conversion frequency, also ensures extremely low and uniform horizontal and vertical directivity.

The advantage of this feature is that it provides a wide range of stereo images while providing rich and detailed sound throughout the room.

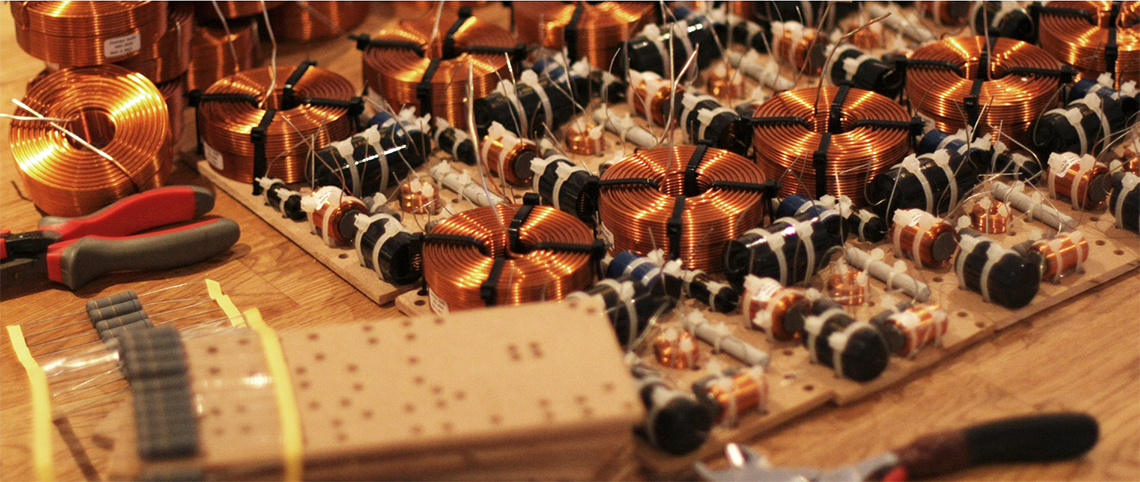

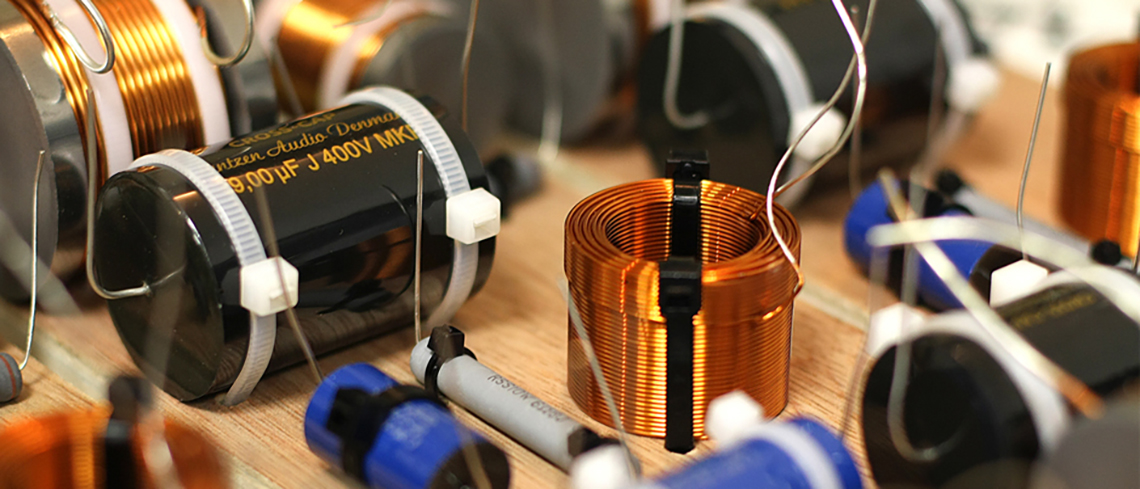

Internal components

To some extent, the internal circuit is the nerve center of the acoustic enclosure. At Recital Audio, we attach great importance to speaker filter components and internal wiring network.

Internal components are invisible to users, so they are often ignored to reduce the manufacturing cost from connecting terminals to speakers, but internal components play an important role in the overall design of acoustic housing and sound recovery quality.

From our point of view, all components and components must be correctly and intelligently selected to provide maximum satisfaction and hearing quality. This is why Recital acoustic enclosure is specially equipped with components, connectors and cables. These components, connectors and cables are not only high-end, but also most importantly, they are very suitable and appropriate in size according to their role and position in the electrical schematic diagram of acoustic enclosure.

Although "Recital PM" filtering technology requires a relatively large number of passive components to achieve overall efficiency, the scheme has been widely optimized to ensure that only a minimum number is required in the process of audio signal transmission.

The large inductance of heavy and heavy media filter is up to 1kg per unit. These auto coupling devices are made of high cross-section enamelled copper wire and wound on magnetic medium to reduce resistance loss. The selected magnetic core is "soft magnetic composite" SMC type, with high saturation induction strength, good permeability and very low hysteresis loss. Your speakers will benefit from a dynamic, vivid and serious media register, completely controlled by the amplifier.

In order to achieve perfect neutrality at higher frequencies, other more specific impedance adaptive inductors are also realized. These self can be "air" type or "magnetic core" type, and have specially optimized characteristics (inductance / resistance) to realize the transmission function of surgical accuracy. In addition, all capacitors used are metallized polypropylene film type with high precision. They only play the role of pure filter capacitor and will not produce noise related to the component itself.